The ammonia opportunity

The growing global ammonia market

Ammonia is the second most widely produced chemical in the world. Globally, demand for ammonia is growing rapidly, with low-carbon ammonia supply set to increase 22 to 30 times by 2030.

Ammonia is vital for modern life. Most of the ammonia currently produced is used in fertilisers, which are critical to feeding the growing world population. Ammonia is also widely used in refrigeration, water treatment, manufacturing and mining.

While traditional ammonia production methods are carbon-intensive, the emergence of low-carbon ammonia is transforming its potential.

Low-carbon ammonia is uniquely versatile and valuable. It can help decarbonise our food chain, chemicals sector, and manufacturing industries.

Ammonia will also play an essential role in our energy transition. It can be used directly as a clean fuel for power generation and in marine engines, with huge potential to decarbonise shipping. With high energy density, ammonia is also an efficient energy carrier which can drive forward the development of the UK’s hydrogen economy.

With its advantages as an import/export destination and hub for world-class innovators, the UK is well-positioned to be a global leader in the expanding global market for ammonia and ammonia solutions. Through the 1900s, engineers in the UK pioneered new ammonia use cases and more efficient production processes, and the UK supplied almost 10% of the global market. With a wealth of existing skills and expertise in this industry, and strides forward in ammonia innovation, we now have a chance to build on this legacy.

This is a significant, strategic opportunity that we should not miss.

The benefits of ammonia

Versatility

Ammonia is a valuable and versatile molecule, which is vital for many parts of modern life. Ammonia has long been a key ingredient in fertilisers, textiles, refrigeration and manufacturing. Today, new innovations mean that ammonia can also be used as a hydrogen carrier and sustainable fuel, and for clean power generation. Transitioning to low-carbon ammonia therefore offers a route to decarbonise these sectors, and wider economic opportunities.

Established infrastructure

Ammonia has been widely and safely traded for decades, as the second most widely produced chemical globally. This means there are established supply chains, transport vessels, handling procedures, distributors and storage terminals across the world. British industry also has a wealth of skills and expertise in handling ammonia, with experience built on longstanding uses of ammonia in refrigeration, manufacturing and fertilisers. This existing experience and infrastructure provides low-carbon ammonia with a significant head-start over other clean fuels, which require new, costly infrastructure for storage and transport.

High energy density

Ammonia is a high-density energy carrier. It can be stored as a liquid at moderate temperatures and pressures. This makes it far more efficient to transport and store than other energy carriers like hydrogen, which needs extremely low temperatures or very high pressures.

Decarbonisation accelerator

When produced with renewable energy or with carbon capture and storage (CCS), ammonia offers a low- or zero-carbon solution that can replace traditional ammonia or fossil fuels in hard-to-abate sectors. Low-carbon ammonia is therefore an immediate solution to accelerate the UK’s path to net zero.

Understanding low-carbon, blue and green ammonia

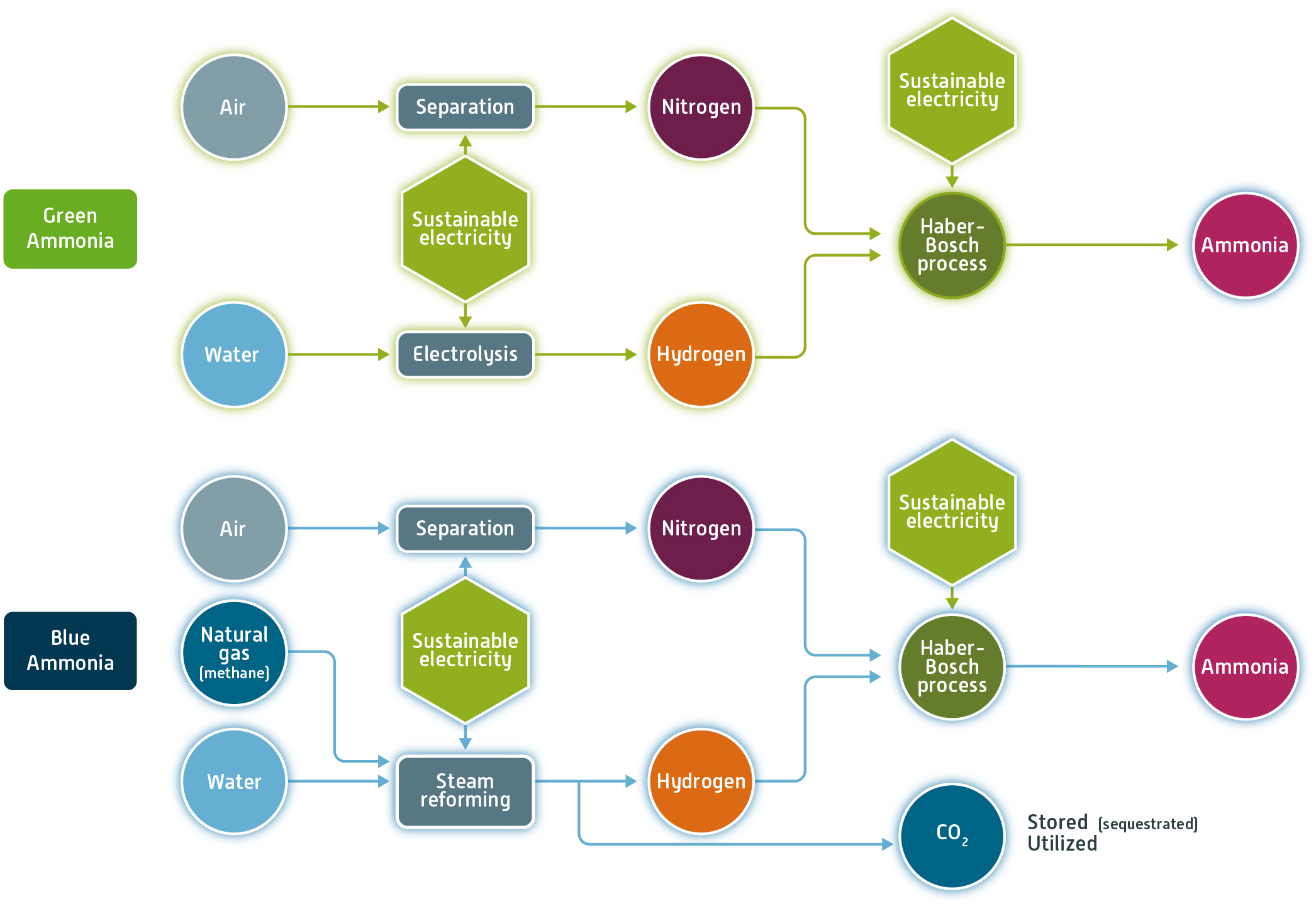

Ammonia is typically produced through the Haber-Bosch process, combining hydrogen with nitrogen from the air to make ammonia. Traditionally, the hydrogen is derived from natural gas, which is energy-intensive and releases significant CO2 into the air.

Low-carbon ammonia is a term for ammonia that has a significantly reduced carbon footprint.

This can primarily be achieved in two ways:

Green ammonia

Uses hydrogen produced through electrolysis of water, which is powered by renewable energy (e.g. wind or solar). This results in a zero-carbon ammonia production process.

Blue ammonia

Uses hydrogen derived from natural gas, but the CO2 emissions are captured and stored underground (CCS is used). This results in a low-carbon ammonia production process.

Is ammonia a safe?

Yes. Ammonia is already produced and transported widely.

Yes. Ammonia is already produced, transported, and used widely. For decades, the ammonia industry has developed and implemented strict safety protocols, engineering controls and emergency response plans. These established procedures provide a strong foundation for the responsible scale-up of the low-carbon ammonia industry.

Safety must be at the heart of our efforts for ammonia to play a key role in the UK’s energy system. That’s why the UK Ammonia Alliance is developing a valuable body of evidence and resources on ammonia safety, based on decades of industry expertise and applied across traditional and emerging uses for ammonia. We are committed to upholding and advancing the highest safety standards across the value chain, from production to end-use.